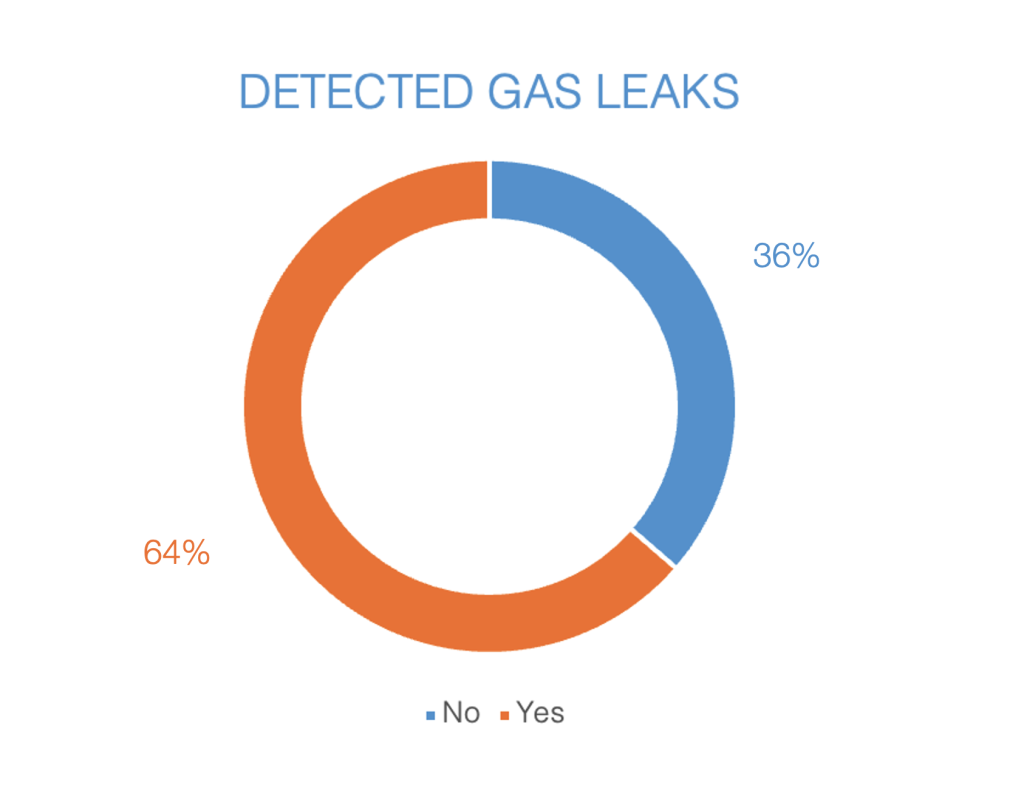

6.4.4 Gas Leakages

Gas leakages were observed in the gas line for 64% of the biogas plants, and the first indication of a possible leak was observed by the smell of hydrogen sulphide in the kitchen, which smells like ”rotten eggs”.

Preventing biogas from leaking is important for the following reasons.

Health Risks: Biogas contains trace amounts of hydrogen sulphide, a toxic gas. If leaked into the indoor environment, these gases can cause health problems such as respiratory issues, headaches, nausea, and dizziness. Prolonged exposure to biogas leaks can have severe health consequences, especially for vulnerable individuals such as children, the elderly, or those with respiratory conditions.

Energy Loss: Biogas is a valuable energy resource that can be utilised. When biogas leaks from the system, it results in energy loss. Instead of being used productively, the energy contained in the biogas goes to waste.

Environmental Impact: Biogas is considered a renewable and environmentally friendly energy source when properly contained and utilised. However, when leaked into the atmosphere, methane—a major component of biogas—a potent greenhouse gas contributing to climate change, is emitted.

To prevent biogas from escaping, the following annual maintenance tasks would help to reduce the issues for existing plants.

Conducting scheduled maintenance, by performing a pressure test at least once a year to detect any potential leakages. Note that minor gas leaks may go undetected during normal operation, as they can be compensated by gas production. Therefore, a pressure test is required.

During the test, all joints and taps need to be inspected for leakage by applying a thick soap solution and observing any foam movement. This method helps identify and address potential leaks promptly.

If planning for a new biogas plant, the following design rationale can help minimise the risk of gas leaks:

Minimise Fittings and Unions: Limit the use of fittings and unions to reduce the risk of leakage. Minimising the number of joints and connections decreases the potential points of failure.

Optimise Gas Pipe Length: Keep gas pipe lengths as short as possible. Longer pipes increase the risk of gas leaks. Additionally, fewer joints, fittings, and shorter pipe lengths can help reduce costs.

By implementing these measures, biogas plant operators can significantly reduce the likelihood of gas leakages, ensuring the safety of individuals, minimising energy loss, and mitigating the environmental impact associated with biogas leaks.