6.4.2 Accumulation of Condensed Water Within the Gas Pipes

During the assessment, it was observed that 91% of the visited biogas plants had an accumulation of condensed water within the gas pipes. This issue poses several problems, including corrosion of the metallic components, reduced gas flow, and increased maintenance requirements.

The presence of condensed water is primarily a result of the biogas leaving the digester saturated with water vapour. If the external temperature is lower than the temperature inside the digester, condensation occurs as the vapour cools down along the gas line. This condensate collects within the pipe, leading to blockages over time. Furthermore, when combined with hydrogen sulphide, the condensed water forms sulfuric acid, further accelerating the corrosion rate.

Ideally, the gas line layout should facilitate the free flow of condensed water back into the digester, with an inclination of not less than 1%. If this is not feasible, one or several water traps must be installed at the lowest points.

When using flexible hose pipes for biogas piping, there is a risk of creating hanging U-bends where condensation water can accumulate, particularly if the hoses are suspended above the ground, as depicted in the picture.

To minimise this issue, it is advisable to avoid flexible hoses for the gas line, except for connection purposes of stoves or other equipment where their use is necessary, as shown in the following example.

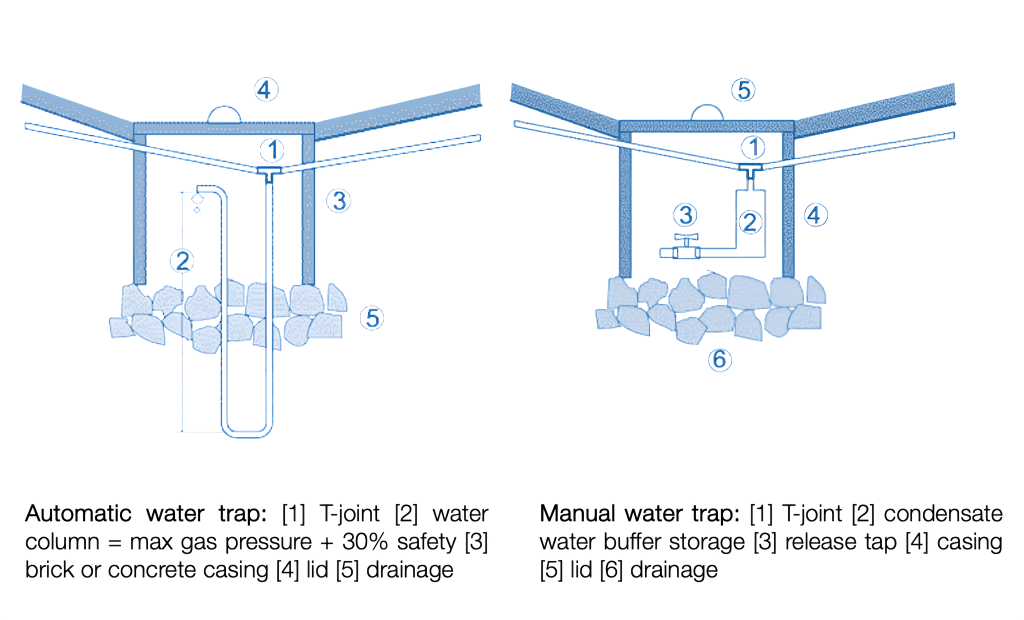

When it comes to water traps, two types can be utilised for gas lines: so-called “automatic” and manually operated water traps.

Automatic traps: are convenient and do not require regular emptying. However, if these traps become empty, they lead to significant and prolonged biogas losses. Additionally, they are not always easily understood, which can complicate maintenance and troubleshooting tasks.

Manual traps: are simple and easy to comprehend, but they must be emptied regularly to prevent the accumulated condensation water from eventually blocking the piping system.

Both traps should be installed within solid chambers and covered with lids to prevent soil from filling them up.

To ensure smooth gas flow, it is essential to remove the condensed water from the pipes weekly to monthly. Regular maintenance and drainage of the condensate will help guarantee the unobstructed passage of biogas through the gas pipe network.