9.12 What are the characteristics and application potential of the products from sludge burning?

Depending on the process, different outputs are generated. These outputs can be used for different applications.

Char

Applications:

- Soil conditioner (for carbon sequestration, composting, soil fertility improvement and pollution remediation)

- Energy storage

- Use in the building sector (additive for bricks or other building materials, insulation, air decontamination, humidity regulation)

- Treatment of wastewater or flue-gas (active carbon filter, pre-rinsing additive)

- Treatment of drinking water (micro-filters)

- Gasification to syngas Combustion for thermal energy recovery

Char is a porous carbonaceous solid that has physiochemical properties suitable for safe and long-term carbon storage in the environment. Char can be used as fuel and energy or directed toward environmental management and carbon sequestration.

Depending on the conditions of the pyrolysis process, the char has different characteristics. The following table shows different components depending on the process temperature.

| Unit | Pyrolysis Temperature Range (°C) | |||

| 300-500 | 550-650 | 700-900 | ||

| Ultimate Analysis | ||||

| H | % | 0.67-2.8 | 0.38-1.2 | 0.19-0.70 |

| C | % | 18.92-47 | 8.15-30.8 | 6.5-33 |

| N | % | 2.13-6.4 | 0.37-3.76 | 0.3-2.98 |

| Proximate Analysis | ||||

| Ash | % | 35-72.0 | 60.3-84.0 | 62.3-82.0 |

| Volatile C | % | 18.4-24.1 | 11.0-16.7 | 4.6-5.7 |

| Fixed C | % | 4.64-12.9 | 1.9-25.4 | 23.9-28.4 |

| Macro-nutrient | ||||

| P | % | 5.6 | 2.4-5.2 | 4.86-5.06 |

| K | % | 0.24 | 1.4-1.8 | 0.31 |

| Ca | % | 3.47-4.17 | 1.32-4.62 | 5.35 |

| Mg | % | 0.35-0.43 | 0.04-0.46 | 0.54 |

| S | % | 4.47-5 | 2.16-5 | 6.17 |

| Micro-nutrient | ||||

| Fe | % | 7.8-8.85 | 10.15 | 11 |

| Zn | mg/kg | 1250-2980 | 845-3900 | 2175 |

| Na | % | – | 8.7 | – |

| Cu | mg/kg | 222-2600 | 163-2700 | 1500 |

| H/C | 0.72-0.87 | 0.22-0.50 | 0.16-0.35 | |

| O/C | 0.13-0.16 | 0.05-0.17 | 0.01-0.18 | |

| pH | 4.7-9.5 | 7.22-9 | 11.7-12 | |

| Total Surface Area | (m2/g) | 4-35.66 | 5.5-37.18 | 9.22-107 |

| Pore Volume | (cm3/g) | 0.0326-0.0738 | 0.0144-0.0681 | 0.0321-0.0894 |

Lower temperatures and longer process times (slow pyrolysis) usually produce a char rich with carbon (C) and low ash content. Slow pyrolysis further results in biochar with good NPK (nitrogen, phosphorus, potassium) that makes the char desirable for soil amendment or organic fertiliser. With increasing pyrolysis temperature, the surface area and porosity of the biochar increases. At the same time the biochar yield, volatile matter, and cadmium sorption capacity decrease.

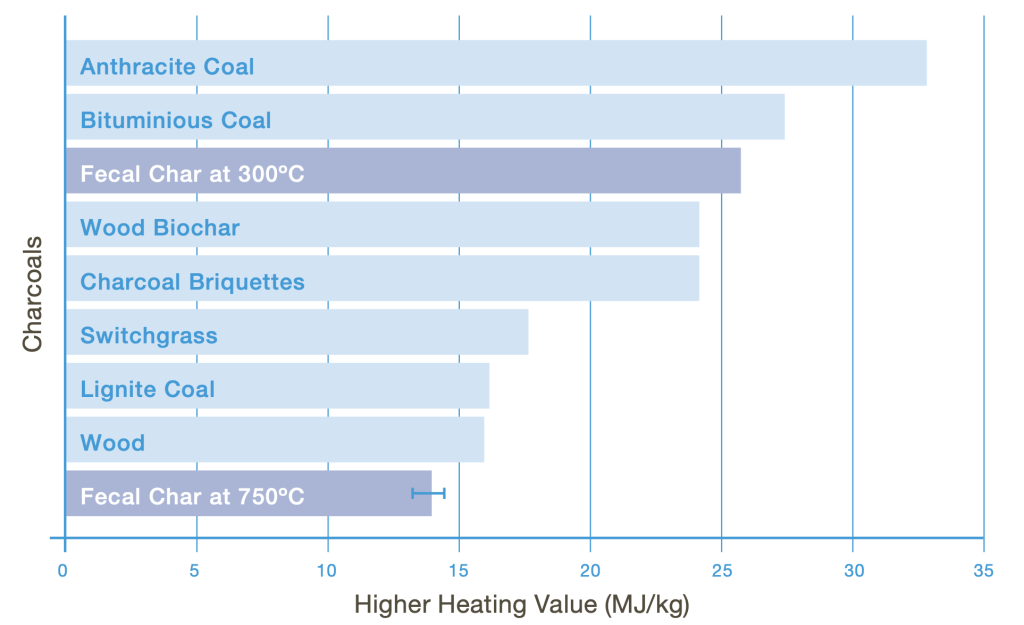

The temperature of the pyrolysis process will also impact the char’s heating value. This is especially relevant when the biochar is intended for charcoal/solid fuel. char can have a higher heating value than wood or lignite coal if the pyrolysis occurs at low temperatures.

When char is intended for the production of briquettes, the following steps need to follow the pyrolysis process:

- Blending and Binding

The carbonised char is crushed into fine particles and subsequently blended with binders. Starch, cassava, molasses or clay can be used as binders. The ideal ratio needs to be determined based on experiments.

Example: In Uganda, the mixture that was able to compete with market-available briquettes consisted of 3 litres of molasses and 6 to 10 kg of clay mixed with 40 litres of water combined with 200 kg of charcoal dust and carbonised faecal sludge char. The charcoal dust and carbonised faecal sludge char ratio may be 60:40.

- Extruding, Moulding and Drying

According to common designs, the blended mixture can be formed using a mould and hammer. A screw press or extruder may compress the mix. Lastly, the briquettes are to be dried (i.e. on racks).

Apart from the process conditions, the sludge will impact the char quality. Char produced from pit latrine faecal waste generally has higher yields, ash, Ca, Fe, surface area, porosity, cadmium sorption capacity, and lower fixed C than sewage sludge.

When char is intended to be commercialised, various organisations provide standards to identify the qualities and characteristics of certain char materials, such as the European Biochar Industry and the International Biochar Initiative. While several biochar initiatives exist in Asia, production based on faecal sludge/biosolids must be regulated. For example, Bangladesh’s Guideline on Sludge Management mentions pyrolysis and gasification as techniques to generate valuable products, but specifications are yet to be developed.

Ash

Applications:

- Soil amendment

- Cover material for urine diversion dry toilets

- Supplement for construction material (e.g. aggregate for roads)

Ash is produced during incineration. Ash can be used as a soil amendment, a supplement for construction material, etc. To be used as a soil amendment, it needs to be ensured that the ash does not contain increased levels of heavy metals that could leach into the soil or be absorbed by plants. Phosphorus, a crucial nutrient in sludge/biosolids, will concentrate, when incinerated, in the ash residue. This makes the ash attractive as a soil amendment. Other components of ash derived from faecal sludge are minerals such as calcium carbonate, silicates and potassium.

If metal contamination is determined, the ash will be used for different purposes (not involving disposal onto soil) or disposed into a landfill.

Syngas

Applications:

- Conversion to liquid transport fuels or chemicals

- Combustion for thermal energy recovery

- Fractioning of specific gases for other purposes

Syngas are mainly produced during gasification but can also result from pyrolysis. It is considered weak because its calorific value is lower than biogas or natural gas. The calorific value of syngas from gasification usually varies between 9 to 13 kJ/m3. Syngas from the pyrolysis process have a lower calorific value of 6 to 9 kJ/m3.

It comprises different gases such as carbon dioxide, carbon monoxide, hydrogen, methane, ethane, ethylene, propane, sulphur oxides, nitrogen oxides and ammonia. Syngas can be used for energy production and heat generation. Since gasification requires drying of the sludge as a pre-treatment, the syngas may be used to generate heat for this process step.

| Syngas Constituent | Composition |

|---|---|

| Carbon Monoxide | 10% – 60% |

| Hydrogen | 20% – 30% |

| Methane | 0% – 30% |

| Carbon Dioxide | 5% – 15% |

| Water Vapour | 2% – 30% |

(Note: composition varies based on technology type and mode of operation)

Heat (Thermal Energy)

Application:

- Conversion to electrical energy using turbines or CHP engines

Heat is the main product of the incineration process. It is usually used for energy recovery. It can be used to produce steam, which drives turbines to generate electricity or as a heat source, i.e., for thermal drying of sludge.

For further information, please click on the Materials tab at the top of the page.