6.4 NEWgen Back-End Technology

Elefo Biotech Private Limited offers a treatment solution for all types of wastewater based on a patent from the University of South Florida.

The NEWgen (NEW = Nutrients, Energy, Water) is a prefabricated and containerised treatment unit offered by Elefo, available in various capacities ranging from 1m³/d to 20m³/d per unit. These units are designed with modularity, offering flexibility by adding modules to meet specific treatment requirements.

The NEWgenerator can be integrated as a secondary treatment step compatible with various wastewater sources. It can be seamlessly installed after solid and liquid separation or biological pre-treatment, such as a septic tank.

6.4.1 How does the system work?

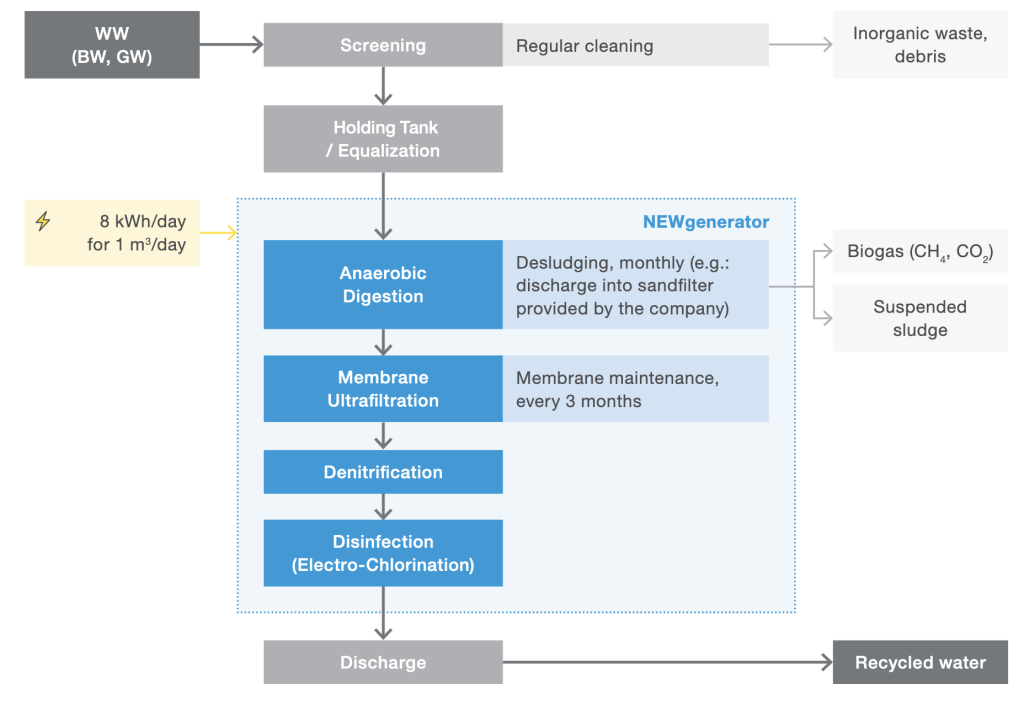

The NEWgen treatment system consists of several key treatment steps, each playing a specific role in treating wastewater or effluent. Here is an overview of the different treatment steps of the NEWgen:

Pre-treatment

Wastewater is first collected in an equalisation tank. A pump then moves the wastewater from the tank through a screen chamber with a 12mm screen to remove larger solid particles before entering the high-rate anaerobic digester.

Anaerobic Digestion

Inside the high-rate anaerobic digester, solid and liquid components of the wastewater are separated. Specialised microorganisms break down organic pollutants in an oxygen-free environment, converting organic matter into methane and carbon dioxide. The effluent from the final chamber is directed to a membrane for further treatment.

Membrane Ultrafiltration

The system utilises an ultrafiltration membrane with tiny pores that selectively allow only water to pass through. This effectively blocks solid particles and pathogens from crossing the membrane, resulting in pathogen-free and solid-free effluent. The particles rejected by the membrane are fed back into the anaerobic digester for further treatment.

Denitrification (NCS Tank)

The Nutrient Capture System (NCS) tank consists of multiple chambers. One of these chambers contains a special zeolite-type material that efficiently removes nutrients from the wastewater. Another chamber uses activated carbon to enhance water quality further. Denitrification is important for reducing nutrient pollution in the effluent. It might be omitted if the effluent is used for irrigation.

Disinfection

In the final step, the effluent is disinfected using electro-chlorination. Electro-chlorination involves using electrical energy to generate chlorine from salt in the water. This disinfection step ensures that the treated effluent is free from harmful microorganisms and pathogens before reusing or releasing it into the environment.

Solids Management

The settled solids from the anaerobic digester are periodically removed and retained in a sand filter.

6.4.2 Treatment Performance

The treatment process employed by NEWgen consistently produces high-quality effluent that complies with ISO 305000 standards. This ensures its safety for various reuse options, such as flushing or irrigation, and for environmentally responsible disposal into water bodies.

6.4.3 Space Requirement

Depending on the specific unit, the area required can range from 6 to 15 m2 per unit.

6.4.4 Energy Requirements

The system requires electricity to operate. The NEWgen100 uses 8kWh/day, and the NEWgen1000 uses 25kWh/day. Solar panels can supply this energy.

6.4.5 What are the O&M Requirements?

The system needs maintenance for its membrane, ion exchange system, and other components, besides desludging. The maintenance tasks are as follows:

- Desludging the system into a sand filter (This can be automated if preferred)

- Maintaining the membrane

- Regenerating the ion exchange system

- Removing the dried sludge from the sand filter

- Replacing the activated carbon in the system

- Replacing the membrane

- Replacing the electro-chlorination cell (if used)

6.4.6 What are the Benefits and Limitations?

The following table outlines the benefits and limitations of the Elefo NEWgen 100 system.

| Benefits | Limitations |

|---|---|

| Small footprint | Regular maintenance is required |

| Treatment according to ISO30500 | The system will require a start-up phase if stopped for over 6 months |

| Portable and prefabricated system that is easy to install | The electronic and electrical system needs protection against water |

| Automated treatment system | Requires electricity for operation |

| Remote monitoring | Has to be aboveground or in an accessible subsurface enclosure (e.g. building basement) |

| Robust and can treat a variety of influent quality | |

| Can be stopped and started without affecting the performance of the system | |

| Pathogen free effluent |

6.4.7 Example

- Following commercialisation, USF tech provides sanitation to South Africa (Link)