Geotube - Filtration

Description of the emergency context

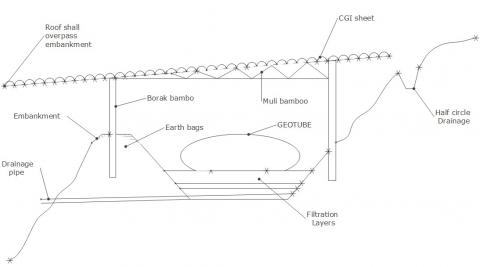

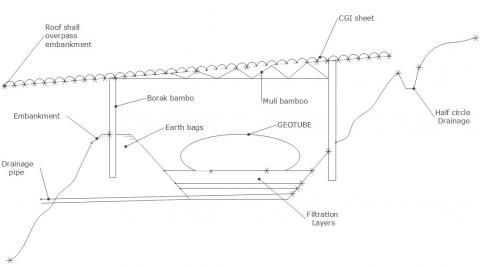

This approach uses a combination of Hydrated Lime Treatment, Geotextile Tubes known as ‘Geotubes’ and Filtration. In the first step, the faecal sludge is pumped out of the pit latrines using mechanical sludge pumps. The sludge is emptied into barrels with a lime (calcium hydroxide: Ca(OH) mix. The stabilised sludge is then poured into a Geotube from barrels through a mesh screen to remove any solid waste. A Geotube consists of a permeable membrane which allows for dewatering of the sludge. The liquid portion of the sludge drains out of the Geotube into a primary filtration unit consisting of three layers of filtration media. This effluent then flows into a secondary filtration unit after which it can be discharged into the environment. The solid fraction of the sludge is retained inside the Geotube and then can be transported to a disposal site or incinerated. The dried sludge and effluent are not fully stabilized and may require further treatment or storage, depending on the desired end-use.

Project Details

Pathogen reduction

Solid/liquid separation

TSS and TDS reduction

Gravel filter

Sand filter

Public toilets

Septic tank connected by greywater

Sludge

Still have questions?

You could not find the information you were looking for? Please contact our helpdesk team of experts for direct and individual support.