Constructed Wetland

OCTOPUS Case Study

Implemented by:

08 June 2019

Description of the emergency context

Kutupalong camp has a natural terrain with hills and canals flowing through the downhills. The forced Myanmar inhabitants have their shelters mostly at different levels of the hills, which makes it difficult to desludge toilets pits.

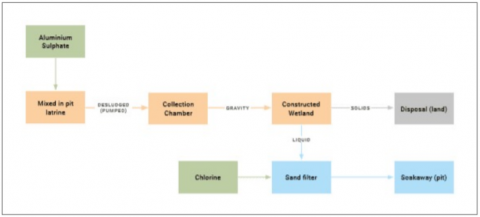

Description of the treatment process

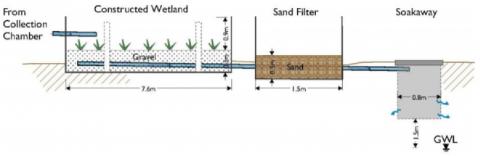

The constructed wetland is a biological treatment unit to treat faecal sludge and wastewater. The constructed wetland has been re-engineered here to achieve primarily as separator of solid and liquid fraction of the raw faecal sludge and then the separated liquid portion undergoes to filtration media for further treatment before discharging into the environment.

The solid portion is treated biologically in mostly aerobic condition in presence of thermophilic bacteria. The presence of Cana Indica (or other available suitable plants) facilitates the nitrification and denitrification process and is responsible for NO3- removal from faecal sludge. Through the process of active bacteria inside the porous media of constructed wetland and on the surface of hay, it stimulates BOD, COD removal. The filtration media facilitates PO4- and TDS removal.

At present, final sludge is planned to be buried safely. However, it may have potential to be used as soil conditioner.

Assessment & design feasibility

The sludge is transported to the intermediate transfer station located at the uphill side of the camp. Once the sludge is transported to an intermediate transfer station, it goes to the constructed wetland located at the downhill side by gravity. An underneath pipe connects the transfer station to the constructed wetland. The treatment plant will be soon decommissioned as it is set up in a flood prone area.

Construction

The CW is within an excavated bund, lined with clay. This doesn’t ensure proper watertighness and thus results in pollution hazards. Walls have been built up by 1m around the beds and are made of metal shuttering (recycled oil drums) and backfilled with earth. This design has been modified to increase resilience against flooding, and should be considered on a site specific basis. The sites is fully enclosed with fencing and a plastic roof. The infiltration pit is made of concrete manhole (MH) rings. Due to the terrain in the CXB camps, the site has extensive slope stability using sandbags and geotextiles. Developing constructed wetland requires technical experts for siting, site preparation and analysis, construction, installation and most importantly operation. Appropriate plants selection for the constructed wetland also requires technical expertise on such system.

![]()

Operation & Maintenance

Faecal sludge needs to be dosed steadily (no shock load) in the constructed wetland to facilitate aerobic bacterial environment inside the porous media and to limit inhibition effect. At present, we are loading with 10m3/week to develop biological environment at the constructed wetland. Once the plants will survive and adapt in the local environment, the dosing of faecal sludge can be higher (15-20m3/week).

Design can be re-engineered and scaled up for higher capacity. Settled aerobically digested sludge accumulates until the wetlands are full (approximately after 6-8 months of average 15-20m3/day operation). When full, thickened digested solid sludge is buried/ disposed of or it may be used as soil conditioner. The design includes chlorination at the effluent leachate treatment unit. The chlorination dose is repeated once per week. This method is however not proven efficient. Nine constructed wetlands are managed by a team of 10 people. Workers involved in the emptying, collection, transport and safe disposal of excreta are provided with Personal Protective Equipment (PPE) to protect their health and safety. Plants need some time to adapt to the constructed wetland, they may need to be planted several times at the beginning period. In some cases, the filtration media of the constructed wetland might be clogged and manual turning and shifting may be required.

Lessons learned

The treatment plant will be soon decommissioned as it is set up in a flood prone area.

Contexts where the technology is applicable:

• Decentralised approach 35m2 for each unit

• Mechanical collection and gravity-fed transportation of sludge is already designed and implemented

• Can be applicable for flat terrain also with intermediate transfer station connecting with chained collection system

• Where there is adequate technical capacity on the loading and operations of constructed wetlands

Contexts where the technology is not applicable:

• Not anticipated yet as system can be reengineered according to the context

• In flood-prone locations, or hillsides prone to landslide

• In locations where surface water runoff will enter the system

• Where there is inadequate technical capacity on the loading and operations of constructed wetlands

Strengths

- The system can be implemented immediately

- Decentralised, simple, low-maintenance design

- Little land is required

- Non-permanent structure

- Enables immediate desludging of toilets

- Includes end-point sludge mineralization in planted bed of constructed wetland

![]()

Project Details

Geographic Location

Cox’s Bazar, Bangladesh

Main treatment objectives

Pathogen reduction

Solid/liquid separation

Solid/liquid separation

Resources needed for operation

Chemicals

Technologies employed

Constructed wetland

Disinfection

Infiltration

Sand filter

Disinfection

Infiltration

Sand filter

Design population

1000 people

Design input flow

1 m2/day

Final outputs

Effluent

Sludge

Sludge

Skills level

FSM specialist for construction

FSM specialist for design

FSM specialist for design

Still have questions?

You could not find the information you were looking for? Please contact our helpdesk team of experts for direct and individual support.