Piloting septic tanks as a long-term containment and treatment option

Syria remains a complex humanitarian and protection emergency characterized by over 11 years of ongoing hostilities and their long-term consequences including widespread destruction of civilian infrastructure, explosive ordnance contamination and the largest number of internally displaced people in the world1. The Syrian civil war displaced over 6 million people inside Syria since 2011 and 4.6 million in North-west Syria (NWS). The majority of IDPs, 1.8 million out of 2.8 million2, live in Northwest Syria (NWS) under overcrowded conditions. Emergency WASH services, shelter and NFIs as well as road and drainage systems construction in NWS is carried out by the NWS S/NFI, Camp Coordination and Camp Management, and WASH clusters. The WASH cluster consists of over 40 NGOs (local NGOs, INGOs and UN-agencies) working and coordinating WASH interventions among others in NWS.

Heavy displacements and rapid influx of IDPs to NWS continuously occur, the highest record for 2022 being 19,545 new internal displacements, largely driven by the deteriorating economy. IDPs are highly dependent on continued humanitarian assistance. Despite, continued support for IDPs in NWS, there are gaps in service delivery and management of the infrastructure. Water trucking services are the only source of water for 73 per cent of IDP site residents and only 24 per cent households are connected to (simplified) sewer networks, indicating a continued need for medium-term investment in IDP sites infrastructure to provide more sustainable, affordable, and safer way to supply water and dispose wastewater. Despite the sector assistance, 24 per cent of IDPs in sites couldn’t access one or multiple hygiene items, 23 per cent faced barriers to effective handwashing. Also, 35 per cent of households reported issues with toilet functionality or wastewater disposal. For people living in IDP sites, insufficient WASH infrastructure or services delivery exacerbates public health risks and impact other needs and require close collaboration between WASH and CCCM. For instance, household-level/shared family WASH facilities, currently a privilege for only around 40 per cent of households in IDP sites, may mitigate the GBV risks and vandalization of communal facilities

WASH services are insufficient in many facilities including in public hospitals and are further negatively affected by ongoing water and energy crises. Due to economic downturn unaffordability of some key hygiene supplies reported by up to 43 per cent of households in communities further deteriorate effectiveness of infection prevention and control. Across northern Syria, the prevalence of Leishmaniasis remains very high due to harmful garbage disposal practices and widespread use of unregulated dumpsites, especially in areas not targeted with vector control activities due to funding shortfalls. WASH needs in schools remain very high and could be linked with dysfunctional public water and sanitation systems the facilities are connected to, water crisis and economic downturn. Over 40 per cent of caretakers in households with children attending school received complaints from children on WASH-related issues, and such factors may contribute to the overall 2.4 million children out of schools (OCHA, 2022).

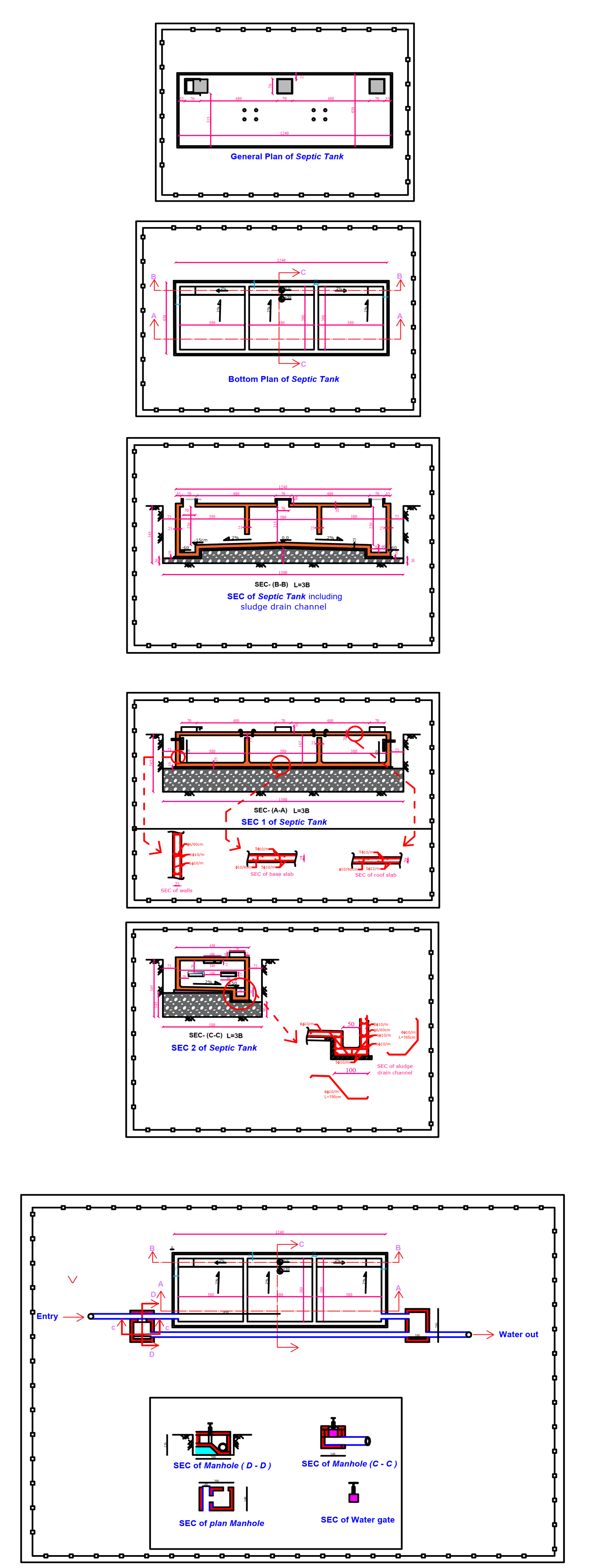

The project piloted a 3-chamber communal septic tank design supported by a study to investigate its efficiency and possible treatment steps that can be added to the system. Implementation was done in partnership with the following implementing partners: ACU, Watan, Saed and Bonyan, with support from different international and funding organizations. The intervention targeted about 14 camps, 4 informal camps and 10 planned camps.

Focus was on provision of better containment and treatment of wastewater, with the aim to reduce overflow of wastewater in camps thus protecting public health, and doing no harm to the environment, as well as preventing breeding sites for mosquitoes and sand flies, therefore reducing spread of malaria and leishmaniasis.

The implemented communal septic tank is a multi-chamber tank with a minimum volume of 50 m3 in some camps and maximum of about 166 m3 in others. The systems receive a peak flow of about 1.3 to 2.6 m3/hour and 0 – 0.9 m3/hours off peak attaining hydraulic retention times varying from 2-15 hours. Wastewater is collected by a simplified gravity sewer line. The network is not extensive since its a decentralized system. Bar screens trap screenings before the manhole and the septic tank. Sludge and screenings is usually transported by vacuum trucks and buried far away from camps. However, there’s no authority inspecting or enforcing this but rather its stewardship of various implementing partners and desludging service providers.

The study monitored the operational and performance parameters, these included pH, temperature, flow rate, retention time, total suspended solids, volatile suspended solids, settleable solids (SS), total dissolved solids, BOD, COD, nitrogen and total coliforms among others. Solids removal was average with high TSS removal than SS, and as expected the system did not remove any TDS. Optimum BOD removal was achieved in some camps, 30-50%, whilst it was as low as 10-20% in some. COD removal ranged from 30-65%, and both nutrients and pathogens removal was negligible.

The septic tank is an old technology that has been traditionally used as an onsite solution to contain wastewater or fecal sludge. The technology is a popular primary treatment method. Despite being an old and popular method, there is relatively not much information or studies about the technology and its effectiveness. Therefore, IOM piloted the study to inform and plan future long lasting wastewater treatment interventions in IDPs camps. The study found out that septic tanks achieve good treatment , 90% TSS removal, 65% COD removal and 50% BOD removal but only if a minimum retention time of 24 hour is met, depending on the daily flow rate. Nutrient an d pathogen removal was negligible, ≤20%. The 3-chamber tank proved efficient in comparison to the 2-chamber tank. However, efficiency can be further improved by adding a holding tank or equalization basin to equalize flow and concentration as well as to help in attaining optimum retention time in the septic tank. Adopting an upflow septic tank is also a favourable option to enhance influent contact with biomass and improve treatment as well as a long first chamber, possibly 0.5 to 0.6 of the total length.

The study was conducted for 6 months during summer and winter periods. Focus was on monitoring the septic tank’s performance in relation to suspended and settleable solids, COD and BOD. This was related to the measured operational parameters, temperature, pH, flow rate and hydraulic retention time. The septic tanks were inoculated before operation for about 20 days. The sludge inoculum was collected from cesspits within IDPs camps. Performance comparison with available wastewater treatment technologies in Northwest Syria were conducted. These technologies include UASB, ABR and constructed wetlands. Sampling was conducted bi-weekly and both operational and performance indicators were monitored. The septic tanks achieved some treatment with high removal efficiency for suspended solids and COD. However, only a few tanks achieved good treatment for all measured parameters.

In conclusion the multi-chamber communal septic tank offers good containment and both primary and secondary wastewater treatment in IDPs and or refugee camps. However, the availability of land space and vacuum trucks or pumps are critical for effective operation and maintenance of the communal septic tanks.

The construction of the septic tanks required the assistance and supervision of field engineers and was done through local contractors using locally sourced materials. The walls and floor of the septic tank was constructed using reinforced concrete. The septic tanks were constructed in IDP sites where some of them have rocky nature and the others have agricultural nature. Attached document shows different IDP sites analysis (TS reduction, BOD and COD reduction, camps population, etc.). Additional graphs and charts can be found here: https://app.powerbi.com/view?r=eyJrIjoiZGNjNWNjYjUtY2JhOC00M2M3LWEzMmIt…

The system required regular desludging which reduce the probability of sludge compaction and attaining active biomass communities (bi-weekly or even weekly sometimes). Additionally, it has limited operation and maintenance options to optimize performance due to the nature of the system.

The efficiency of the system mainly dependent on achieving optimum hydraulic retention time (HRT), and there is low flexibility to regulate the flow in order to reach the HRT.

The tank cleaning and repairs are done by trained professionals and experienced personnel, who uses PPEs and special tools and equipment.

In summary, the system requires general housekeeping once a week and periodical desludging depending on the load

– To adopt the 3-chamber septic tank with a longer first chamber possibly 0.40-0.5 of the total septic tank length to avoid high velocity plumes and short-circuiting. Higher-velocity plumes through the partition orifices produce turbulent flow with eddies that suspend solids and allow untreated sewage to short-circuit directly to the outlet. The suggested design is likely to optimize solids-liquid separation by encouraging a well-developed, quiet, laminar flow regime. The design may also allow the system to behave like a true plug flow system, therefore, improving efficiency

– Add to the system an equalization or holding tank and adopting deep-row entrenchment sludge management instead of uncontrolled solids burial. The addition of a flow equalization tank is likely to improve BOD removal, have a uniform flow and concentration as well as to achieve at least a 24 hour retention time. This may optimize sedimentation and anaerobic digestion processes. In addition, adopting an upflow design improves contact of bacteria with organic matter and therefore, may improve performance of the septic tank.

– Add an outlet filter or a wire mesh to avoid blockages and possible effluent overflow

– Better containment of wastewater, reduced overflow of effluent in camps and to the environment as well as avoids creation of man-made effluent streams

– Reduced risk of child fatalities due to falling in cesspits. Some cesspits had plastic manhole covers and the risk of falls were high. A child death due to that were recorded in 2019.

– BOD and pathogen load reduction before disposal to the environment

– Simple and robust technology

– No electrical energy is required

– Low operating costs and long service life

– Small land area required (can be built underground).

– Can be constructed and repaired using locally available materials

– Can remove 50% of solids, 30 to 40% of BOD and a 1-log removal of E. coli can be expected in a well-designed and maintained septic tank.

– Can be installed in every type of climate, although the efficiency will be lower in colder climates.

– Little to no room for optimization

– Regular desludging must be ensured

– Low reduction of pathogens and nutrients

– Effluent and sludge require further treatment and/or appropriate discharge

Project Details

Syria

Settling-thickening tank

Solid/liquid separation

TSS and TDS reduction

Public toilets

FSM specialist for design

Local contractor for construction

Still have questions?

You could not find the information you were looking for? Please contact our helpdesk team of experts for direct and individual support.