Case Study: Aerobic Treatment

Location of the case study

Cox’s Bazar

Bangladesh

Resources needed for operation

Chemicals

Electricity

Capex / design input flow

2 022.00 USD/m³/day

Skills level

FSM specialist for construction

FSM specialist for design

FSM specialist for operation and maintenance

Main treatment objectives

BOD / COD Reduction

Nutrient reduction

Pathogen reduction

Technologies employed

Activated sludge

Anaerobic baffled reactor

Disinfection

Glass beads filter

Settling-thickening tank

Source of sludge

Pit latrines affected by groundwater infiltraton

Real input flow

3 m³/day

Opex per real input flow

5 USD/m³

Type of output

Effluent

Sludge

Real input flow

2 m³/day

Time construction and commissioning

1 year(s)

Required space

0.02 m²/person

Design population

20 000 persons

Local constraints

Flood prone area

High water table

TS Reduction

78 %

Design input flow

10 m³/day

COD Reduction

88 %

Description of the Emergency Context

Not detailled

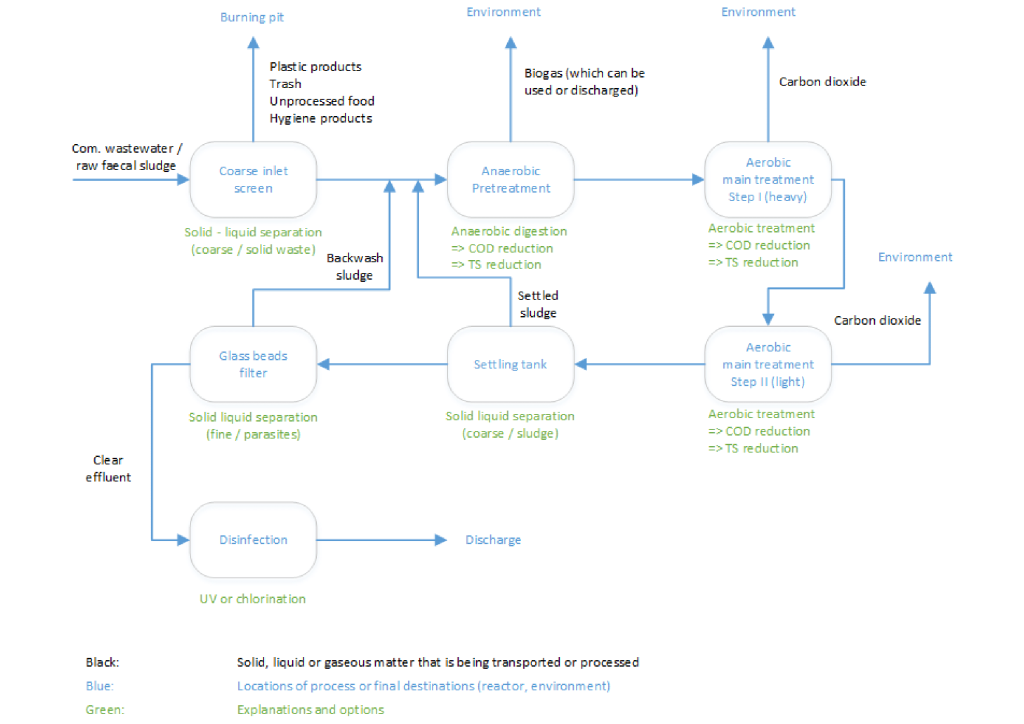

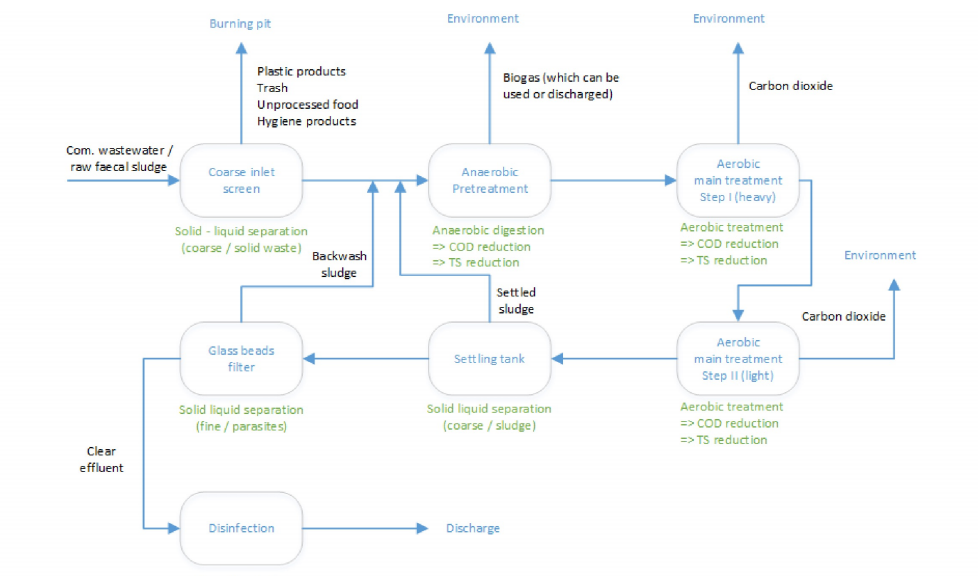

Treatment Process

The anaerobic baffled reactor is used as pretreatment, to remove solids from the waste stream. The waste then moves to two reactor tanks in series. The aeration of the incoming faecal sludge in the a reactor tanks leads to the breeding of bacteria that metabolize the organic content (COD/TOC (Total Organic Content)) together with the oxygen, turning the organic content into a gas (carbon dioxide).

The supernatant from the two reactor tanks is transferred to a settling tank, where the remaining solids are separated. The supernatant of the settling tank is then passed through a glass bead filter, which is regularly backwashed, for the removal of parasites and parasite eggs. Finally, the liquid is disinfected by chlorine or UV. Sludge from the settling tank is added to the reactor tank. Reactor tank sludge is treated by anaerobic digestion or lime treatment.

Assessment & Design (Feasibility)

The plant is located next to a creek line that has been widened. It is a topography composed of plains and plateaus.

The site has yet to be flooded, however potential flooding could occur in large rainfall event (e.g. 1 in 50 years).

Construction

Equipment package comes with 12 kVA genset and wiring for connection to renewable energy. Water is needed for inception and backwash.The aerator and oloid are coming from Germany, the Oxfam tanks are also imported from abroad.The construction lasts 2-5 days and the inception time is about 4 weeks or more depending on waste characteristics. The cost is $180,000 per treatment line ($9.00 per person) excluding works, plus local materials (e.g.fencing, gravel). It includes genset rather than renewable energy source. The skills required for set up and oversight is aerobic treatment expertise.

Operation and Maintenance

The skills required for daily operation and maintenance is basic mechanical and electric skills & low skill labour. Water is needed for inception and backwash. A fully functional faecal sludge quality laboratory is a requirement for this unit. The cost is $5 per m3 treated, reduced with use of renewable energy. It excludes sludge transport cost.

There is a 2.2m3 inflow every day, and 2.5m3 of output is produced every 3 days, with a 10% solids (100 kg / m3). The output sludge production in comparison to sludge input flow is 38 kg/m3. BOD is not measured. The COD average influent concentration is 23,600 mg/L and the COD average effluent concentration is 1,100 mg/L. The COD reduction is 88%. The faecal coliforms are fully removed due to current chlorination dosage. The average TS influent concentration is 22 g/kg and the outlet concentration is 5 kg//kg. The TS reduction is 78%.

The average pH for influent is 8.1 and the average pH for effluent is 7.9. The helminth eggs average influent concentration is 266 eggs/g and the helminth eggs average effluent concentration is 3 eggs/g. The helminth eggs reduction is 98%.

The unit does not produce strong odours or attract insects but the unit should be as far from settlement as possible while still allowing for efficient delivery of faecal waste. Washing facilities and PPEs are available. Drainage is implemented. The site is fenced. Fencing and security are needed for health and safety and theft prevention. An estimated 0.1 m3 of dried sludge and 10 m3 of treated wastewater is discharged per day (wastewater can safely be used for irrigation or added to a surface waterway)

Strengths

- Odour and solid reduction

- Low land use

- Effective and efficient

Image Gallery

Key Resources and Tools

Still have questions?

You could not find the information you were looking for? Please contact our helpdesk team of experts for direct and individual support.